VORON 350 BED

We offer these beds in standard or magbed versions.

Our magbeds are a top magnet design bed, meaning that the magnets are slightly below the surface of the magbed. This gives a very superior holding power, however, it does require a very good quality build plate, such as Buildtak or KB3Ds. The manufacturers of those flex plates use a 0.5mm thick sheet. Thinner sheets may dimple slightly under the magnet. A lot of China build plates are not up to the challenge.

Now, a word of warning, if you are using an inductive sensor, you WILL have issues leveling your bed if you choose the magbed option. Our magnets are very strong, and they mess with inductive sensors, some capacitive sensors, and even BLTouch. If you choose to use BLTouch, you will have to dodge magnets while probing your bed. We do not provide the coordinates for this, so it will be up to you to figure out.

We also have added two additional threaded 5mm holes closer to the center of the build plate, allowing you to put the wiring between the mounting extrusion, instead of over them.

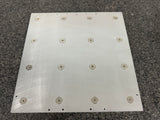

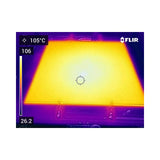

The Voron 350 bed is machined out of 9mm thick 5083 Aluminum Cast Tooling plate. These beds have been optimized to work on the mounting points for the Voron 2.4 and Voron Trident (1.8 doesn't support a bed this large). We also check each bed on a granite surface plate to make sure it is within specs for use on your Voron printer. All beds have been checked to be under 0.2mm overall flatness, ultraflats are all +/- 0.05mm, or in plain terms, no more than 0.1mm out of flat. The fuse and thermistor holes are threaded m5x0.8.

Please note if you have difficulty threading a bolt from the bottom side of the bed, just run a bolt down from the top all the way thru and it will clean up the last little bit of thread.

- Weight: 8 lbs (approx)

- Length: 355mm

- Height: 355mm

- Thickness: 9mm

IMPORTANT NOTE: If at any point you decide to remove the magnets, first of all, when reinstalling the screws, turn the screw backwards until you feel the threads in the screw jump the threads in the bed. Once you feel that little bump, turn the screw in until it gets to the "screw stops turning point" with zero strength behind it. Once the screw has stopped turning, tighten it 1/32nd of a turn and NO MORE. Overtightening WILL shatter the magnets.

We ship within one business day. Message us if your country is not available, and we will add it.